TREKS K-200

Experience the ultimate performance and speed with our TREKS K-200 CNC router processing centre. Our state-of-the-art centre is specifically designed to cater to the wood processing technologies of today, ensuring high-quality processing and unmatched efficiency. Trust us to deliver the best in class performance for all your wood processing needs.

· TREKS K-200 CNC Advantages

- Treks K200 CNC Router has a sturdy 3700kg chassis that ensures zero vibration and maximum processing flexibility.

- Treks K200 is designed to provide easy machine use, making it a user-friendly option.

- The absolute servo feature available in Treks K200 axis motors allows the user to work without reference, making it highly convenient.

- The Treks K200 model comes with optimized software and user dynamics, ensuring that it is always user-friendly.

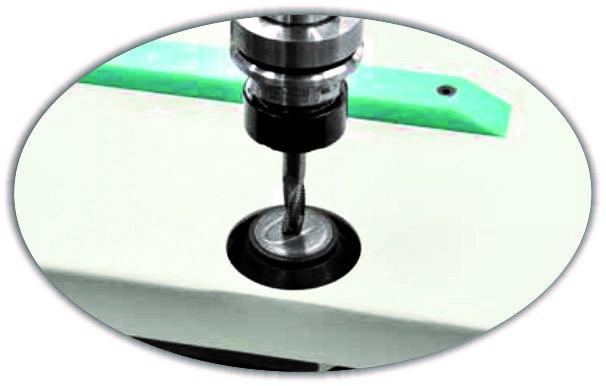

- Treks K200 also has a table protection system that prevents the spindle or processing knife from touching the table, thus protecting both the user and the machine from possible accidents.

- Our Treks K200 model uses the TPA control program of Italian origin.

· TREKS K200 CNC Features

- The processing features are equally efficient throughout the entire processing area.

- Standard air-cooled machining registers are provided through air-cooled HSD or HITECO Brand Spindle.

- There's a highly efficient vacuum unit in all areas that prevents error removal in the processed product and ensures minimum energy consumption.

- The machine offers automatic tool changing with 14 tool holders, and it performs fully automatic processing.

- You can change your tools as you wish with the automatic tool-changing system.

- The entire table in the Treks K200 section applies 250 m3/s vacuum. Moreover, the Spindle's content is specially designed with a total vacuum of 500 m3/s to ensure that the processed area is held more tightly to the table.

- The Treks K200 table protection system prevents the spindle or machining knife on your machine from touching the table, protecting you and your machine against accidents that may occur during operation.

· TREKS K200 CNC Optional Features

Our Treks K200 model has several optional features available. You can add an optional rotary magazine to the model. Additionally, the standard 14 tool holders can be increased by 14 or its multiples if desired. You can also opt for automatic sweeping, automatic loading elevator, and automatic unloading bench. Lastly, it's possible to add multiple hole groups to the model.

Technical Specifications

WORKSPACE : 2100 X 2800 X 200mm

DRIVE GEAR : 2-module helical hardened rack

gear, WSP branded ( German Origin)

SPINDLE MOTOR

RATING : 12 Kw

with automatic interchanging tools ISO 30, OLI-branded ( Italian origin)

SPINDLE MOTOR

SPEED : 24000 RPM

TOOL MAGAZINE : 14-piece fixed magazine with 14 İso

30 tool holders

RAIL AND CONVEYOR : Y-axis 35mm, X-axis 25mm rail

and conveyor

LUBRICATION: 13-zone octopus-type automatic

lubricant pump

DRIVE MOTORS: X and Y axes 1,5Kw, Z axis 0,75Kw with a stopper,

Delta branded Ethercat servo motor and drive

X AXIS SPEED: 80 meters/minute

Y-AXIS SPEED : 80 meters/minute

Z-AXIS SPEED : 15

meters/minute

CAM PROGRAM : ALPHACAM 2D (For Rent)

CONTROL SYSTEM : TPA Pc Control Unit ( ItalianOrigin)

BLADE RESET: Automatic

AUTOMATIC SWEEP : Standard

VACUUM : 2 x 250 m3/h, Becker

branded dry vacuum pumps

VACUUM TRAY: 20mm, 5083 serial Aluminum tray, 6-zone

automatic electrical vacuum chamber

READY TO USE

CAPACITY: Min 15Kw,

Max 27Kw

WEIGHT : 4800 Kg

AIR CONSUMPTION : 6-8 Bar

DETAILS

Machinery operating with CNC Technologies are naturally expected of high standards of precision by their users. Besides a precisely honed construction and a rail system with the right amount of thickness and quality to obtain the expected precision, the decision to choose the rack gear is also crucial for obtaining the expected amount of precision in the machining and cutting processes. Our company prefers the German-origin, honed and hardened rack and pinion gears due to their longevity and precision qualities compared to the lower-cost straight gears or helical soft rack and pinion gears.

|

The Italian OLI/ HITECO/ HSK brand spindle motor which can produce 12Kw of power and has 24000 rpm is used in Treks K200. İSO30 ER 32 is the tool holder of choice.  |

The interchanging tools function is standard as a fixed magazine with İSO 30 ER 32 in Treks K-2000 The interchanging tools function is standard as a fixed magazine with İSO 30 ER 32 in Treks K-2000

|

Rail and conveyors are among the most important parts of a CNC bench. The whole model range produced by our company comes standard with high processing quality and longevity. All the rail and conveyors, without exception, from the biggest to the smallest are used with the above-mentioned thicknesses in all their benches.

|

The planet reductor which is among the many reductor types, is a machinery equipment commonly used in many different industries, which can cope with high amounts of torque. Planet reductors which can work in harmony with servo motors help the distribution of torque to different gears.. They also provide high operating efficiency at low rpm. Our reductor of choice in Treks K200 is the LIMING brand with a 120mm perimeter and has the capacity of sevenfold reinforcing, which can cope with high levels of torque with its 32mm. Axle diameter and has a superior level of coupling with servo motor axle compared to other brands.

|

The servo motor capacity choices in Treks K-3000 are Ethercat communicated servo motor and drive with 1,5kw for the X and Y axes and 1Kw with a stopper function for the Z axis

|

2 piece Becker-branded dry vacuum pumps with a 250m3/h vacuum flow are used in Treks K200

|

An Italian-originated TPA Pc controller with high safety standards is used as the control unit in Treks K-200. TPA Pc Controller enables its operator to solve the daily problems caused by the alarms bay having an internal post-alarm solving unit. TPA can prevent operator-based errors in the nesting executions and can execute several cutting files simultaneously with the help of AI Technology

|

With the help of automatic blade reset; after each blade is measured, their off-set data is automatically stored in Treks K200. Moreover, each off-set can determine its limit and the blades cannot penetrate the tray in jog and program modes.

|

DO YOU HAVE ANY QUESTION? CONTACT With our Export Manager Email: [email protected] / Mobile: +905345969770 TITLE: MECH ENGG. VOLKAN EDE

|